Everything You Need To Know About OSHA Railing Requirements

When it comes to workplace safety, the Occupational Safety and Health Administration (OSHA) plays a pivotal role in setting and enforcing standards. OSHA has established specific requirements for railings in various industrial and commercial settings to protect workers and ensure their safety. This article will provide you with a comprehensive understanding of OSHA railing requirements, including stair railing requirements, railing height, and hand railing requirements.

Let’s Overview OSHA Railing Requirements

OSHA’s railing requirements are designed to prevent falls and protect workers from potential hazards. These requirements apply to various workplaces, including construction sites, factories, warehouses, and other industrial settings. The key aspects of OSHA railing requirements encompass the following:

Standard Railing Height

In many situations, standard railings are essential for preventing falls and ensuring workplace safety. These railings should have a vertical height of 42 inches, according to OSHA railing requirements. This height provides a protective barrier against falls from elevated surfaces.

Low Railings

Certain situations may require railings with lower height specifications to meet specific needs. OSHA recognizes these variations, particularly when the risk of falling is minimal. In cases where there is no significant risk of falling from an elevated surface, railings may have a height of 30 inches. This lower height is permissible in areas where the potential for accidents is reduced.

Specialized Requirements

In addition to the standard and low railing specifications, OSHA provides specialized requirements for particular industries and scenarios. For instance, maritime industries have their own regulations for railings on vessels, and scaffolding has unique requirements for temporary structures.

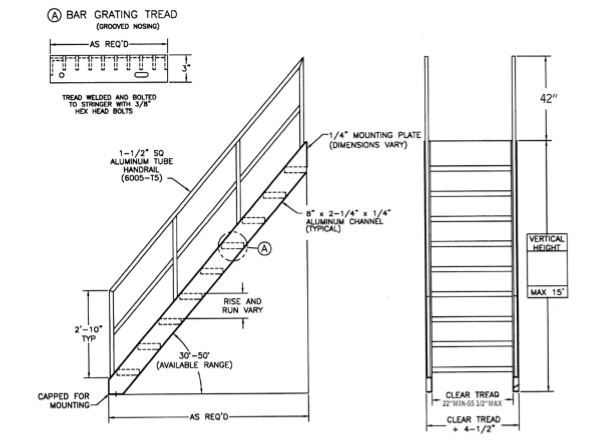

OSHA Stair Railing Requirements

Stairways are one of the most common features in many workplaces, as they pose a significant risk if they are not properly installed. OSHA stair railing requirements are in place to ensure the safety of employees and visitors. OSHA mandates that all stairs with four or more risers or rising more than 30 inches in height must have stair railings. Here are some key stair railing requirements and essential aspects that should be considered;

-

Standard Railing Height

Stair railings must be at least 36 inches in height from the upper surface of the top rail to the surface of the tread. In addition to the top rail, there should be a handrail that provides additional support, typically 34 to 38 inches above the nosing of the tread.

-

Strength & Durability

Stair railings must be capable of withstanding a force of at least 200 pounds applied within two inches of the top edge in any outward or downward direction. This strength requirement is crucial to ensure the safety and stability of the railing.

-

Spacing

OSHA regulations also dictate that the vertical distance between balusters or intermediate rails should not exceed 9.5 inches. This prevents small objects or body parts from passing through, minimizing the risk of entrapment.

-

Construction

Stair railings should be constructed of materials that are sturdy and durable, typically made of steel, aluminum, or wood. They should be securely fastened to the staircase to ensure stability.

OSHA Railing Height

Railing height is a critical component of workplace safety. Properly designed railings provide a physical barrier that prevents individuals from accidentally falling off elevated platforms, walkways, or other potentially hazardous areas. OSHA sets specific standards to ensure that railings are at the appropriate height to offer protection. OSHA railing height requirements to contemplate;

-

Standard Railing Height

Standard railings must have a vertical height of 42 inches. This height ensures that the railing provides adequate protection against falls, especially when working on elevated surfaces. The 42-inch height requirement is a fundamental standard applicable to many scenarios, but it is not the only consideration. There are exceptions and variations depending on the specific situation.

-

Low Railings

In cases where there is no danger of falling from an elevated surface, railings may have a height of 30 inches. This is notably lower than the standard height and may be appropriate in areas where there is minimal risk.

-

Specific Requirements

Some industries or specific tasks may have unique requirements. For example, in the maritime industry, OSHA has specific regulations for different types of vessels, including cargo vessels, tankers, and passenger vessels. These regulations outline requirements for railings, including height, based on vessel type and use.

-

Temporary Structures

OSHA also provides guidance for temporary structures like scaffolding. The height of railings on scaffolding must be at least 38 inches, but additional fall protection measures may be required based on the specific circumstances and height of the platform.

OSHA Hand Railing Requirements

Handrails are essential components of stair railing systems. They provide a secure handhold for individuals ascending or descending stairs. No offense, they serve as an additional safety measure, providing stability and support to individuals using stairs, ramps, and walkways. OSHA has established guidelines for handrails, which include the following:

-

Height

Handrails should be between 34 inches and 38 inches above the nosing of the treads and extend at least 12 inches beyond the top riser and at least equivalent to one tread depth beyond the bottom riser.

-

Location

Handrails should be installed along both sides of a stairway. They must be parallel to the ground and the line of the stair treads. This ensures that workers have a firm grip as they use the stairs.

-

Graspable Shape

Handrails should have a graspable shape, meaning they must be easy to hold onto. Circular handrails should have a diameter of 1.25 inches to 2 inches, while non-circular handrails should have a perimeter dimension of 4 inches to 6.25 inches with a maximum cross-section dimension of 2.25 inches. The gripping surface of handrails should be smooth, easy to grasp, and free from sharp edges or projections that could cause injury to users

-

Strength

Like stair railings, handrails should withstand a force of at least 200 pounds applied in any direction. This strength requirement is essential for the safety of those relying on handrails for support. They should also be durable and not deteriorate over time and also ensure long-term safety.

-

Height

Handrails should be between 34 and 38 inches in height. This measurement is taken from the nosing of the stair tread to the top surface of the handrail.

-

Extension

Handrails should extend at least 12 inches beyond the top riser and at least equivalent to one tread depth beyond the bottom riser. This extension ensures that individuals have a continuous handhold when they start or finish using the stairs.

OSHA Railing Height Requirements for Different Industries

Railing height is a critical factor in fall protection. OSHA specifies the following requirements for railing height:

General Industry

For most settings, including manufacturing facilities, warehouses, and office buildings, OSHA requires railings to be 42 inches in height.

Construction Industry

In the construction industry, railing heights can vary depending on the specific application. Temporary railings, like those used during construction, must be at least 42 inches high. For other construction settings, railings should be 36 inches in height.

Maritime Industry

In maritime work environments, the required railing height is also 42 inches, similar to general industry standards.

4 Common Mistakes to Avoid OSHA Railing Requirements

To ensure adherence with OSHA railing requirements, avoid these common mistakes:

Inadequate Maintenance

Neglecting the maintenance of railings and handrails can lead to safety hazards. Regularly inspect and maintain them to ensure they are in good condition. It is crucial to conduct regular inspections of your workplace to identify any deficiencies in your railings and handrails. Address issues promptly.

Improper Installation

Improperly installed railings may not provide the necessary protection. Always hire qualified professionals for installation. However, once you ensure that railings and handrails are installed correctly by trained professionals who follow OSHA guidelines.

Failure to Train Employees

Employees must be aware of the importance of using railings and handrails. Failure to train them properly can result in accidents. So, provide proper training to employees so they understand the importance of using railings and handrails for safety.

Ignoring Updates

OSHA may revise its guidelines and regulations. Stay informed about any changes to ensure ongoing adherence. You must familiarize yourself and your team with OSHA’s guidelines and regulations. They are readily available on the OSHA website and through their publications.

As you know, OSHA takes workplace safety seriously and enforces railing requirements rigorously. Non-adherence can result in severe penalties for employers. These penalties may include fines, citations, or even temporary shutdowns of job sites until safety issues are resolved. It’s important for employers to be proactive in adhering to OSHA regulations, conducting regular safety inspections, and providing proper training for their workers to ensure adherence.

To Wrap Up the Things

Understanding OSHA railing requirements, including stair railing, railing height, and hand railing specifications, is essential for maintaining a safe work environment. These regulations are in place to protect employees from the risk of falls, a common cause of workplace injuries. Employers must ensure that all railing systems are built to OSHA standards, and regular inspections should be conducted to maintain adherence. By doing so, employers can prioritize the safety and well-being of their workforce while avoiding potential legal consequences associated with non-adherence

Related Posts

360° Video Safety Training for High-Risk Construction

Workplace Safety Survey: What 500 U.S. Workers Revealed